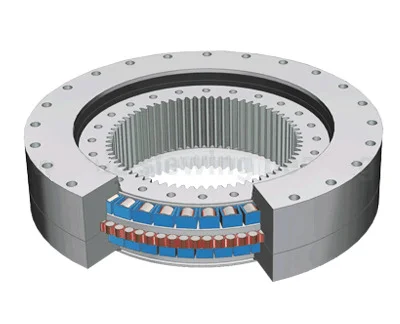

Three Row Roller Bearing Internal Gear

The three row roller slewing bearing has three seat rings,which separate the upper,lower and radial raceways,it made each row of the roller's load capacity can be specified and can bear different loads simultaneously. The capacity load is the largest one compare with the other three models.Due to the large size in axial and radial dimension the solid structure, it is specially suitable for the heavy duty machinery such as wheeled excavator,wheeled crane, ship crane,ladle turrets and the heavy duty mobile crane etc.

Weight/KG: 224-7320

Note: 1. N1 is the numbers of lubricating holes. Oil cup M10×1JB/T7940.1~JB/T7940. 2. The Oil nipple's location can be change according to the user's application. 2. n-φ can change to tapped hole, the diameter of tapped hole is M, and depth is 2M. 3. The tangential tooth force in the form is the max tooth force; the nominal tangential tooth force is 1/2 of the max one. 4. "K" is addendum reduction coefficient.

No.

Inxternal Gear

DL

mmDimensions

Mounting Dimension

Structural Dimension

Gear Data

Gear circumferential force

Weight

kg

D

mmd

mmH

mmD1

mmD2

mmn

mm

dm

mmL

mmn1

mmH1

mmh

mmb

mmx

m

mmD e

mmz

Normalizing

Z 104NQuenching

T 104N

1

133.25.500

634

366

148

598

402

24

18

M16

32

4

10

32

80

0.5

5

337

68

5.0

6.7

224

134.25.500

6

338.4

57

2

133.25.560

694

426

148

658

462

24

18

M16

32

4

10

32

80

0.5

5

397

80

5.0

6.7

240

134.25.560

6

398.4

67

3

133.25.630

764

496

148

728

532

28

18

M16

32

4

10

32

80

0.5

6

458.4

77

6.0

8

270

134.25.630

8

459.2

58

4

133.25.710

844

576

148

808

612

28

18

M16

32

4

10

32

80

0.5

6

536.4

90

6.0

8

300

134.25.710

8

539.2

68

5

133.32.800

964

636

182

920

680

36

22

M20

40

4

10

40

120

0.5

8

595.2

75

12.1

16.7

500

134.32.800

10

594

60

6

133.32.900

1064

736

182

1020

780

36

22

M20

40

4

10

40

120

0.5

8

691.2

87

12.1

16.7

600

134.32.900

10

694

70

7

133.32.1000

1164

836

182

1120

880

40

22

M20

40

5

10

40

120

0.5

10

784

79

15.1

20.9

680

134.32.1000

12

784.8

66

8

133.32.1120

1284

956

182

1240

1000

40

22

M20

40

5

10

40

120

0.5

10

904

91

15.1

20.9

820

134.32.1120

12

904.8

76

9

133.40.1250

1445

1055

220

1393

1107

45

26

M24

48

5

10

50

150

0.5

12

988.8

83

22.9

31.4

1200

134.40.1250

14

985.6

71

10

133.40.1400

1595

1205

220

1543

1257

45

26

M24

48

5

10

50

150

0.5

12

1144.8

96

22.9

31.4

1300

134.40.1400

14

1139.6

82

11

133.40.1600

1795

1405

220

1743

1457

48

26

M24

48

6

10

50

150

0.5

14

1335.6

96

26.3

36.6

1520

134.40.1600

16

1334.4

84

12

133.40.1800

1995

1605

220

1943

1657

48

26

M24

48

6

10

50

150

0.5

14

1531.6

110

26.3

36.6

1750

134.40.1800

16

1526.4

96

13

133.45.2000

2221

1779

231

2155

1845

60

33

M30

60

6

12

54

160

0.5

16

1702.4

107

32.2

44.5

2400

134.45.2000

18

1699.2

95

14

133.45.2240

2461

2019

231

2395

2085

60

33

M30

60

6

12

54

160

0.5

16

1926.4

121

32.2

44.5

2700

134.45.2240

18

1933.2

108

15

133.45.2500

2721

2279

231

2655

2345

72

33

M30

60

8

12

54

160

0.5

18

2185.2

122

36.2

50.1

3000

134.45.2500

20

2188

110

16

133.45.2800

3021

2579

231

2955

2645

72

33

M30

60

8

12

54

160

0.5

18

2491.2

139

36.2

50.1

3400

134.45.2800

20

2488

125

17

133.50.3150

3432

2868

270

3342

2958

72

45

M42

84

8

12

65

180

0.5

20

2768

139

45.2

62.6

5000

134.50.3150

22

2758.8

126

18

133.50.3550

3832

3268

270

3742

3358

72

45

M42

84

8

258

65

180

0.5

20

3168

159

45.2

62.6

5680

134.50.3500

22

3154.8

144

49.8

68.9

19

133.50.4000

4282

3718

270

4192

3808

80

45

M42

84

8

258

65

180

0.5

22

3116.8

165

49.8

68.9

6470

134.50.4000

25

3610

145

56.5

78.3

20

133.50.4500

4782

4218

270

4692

4308

80

45

M42

84

8

258

65

180

0.5

22

4122.8

188

49.8

68.9

7320

134.50.4500

25

4110

165

56.5

78.3